About

Quality Management System

Quality is the standard

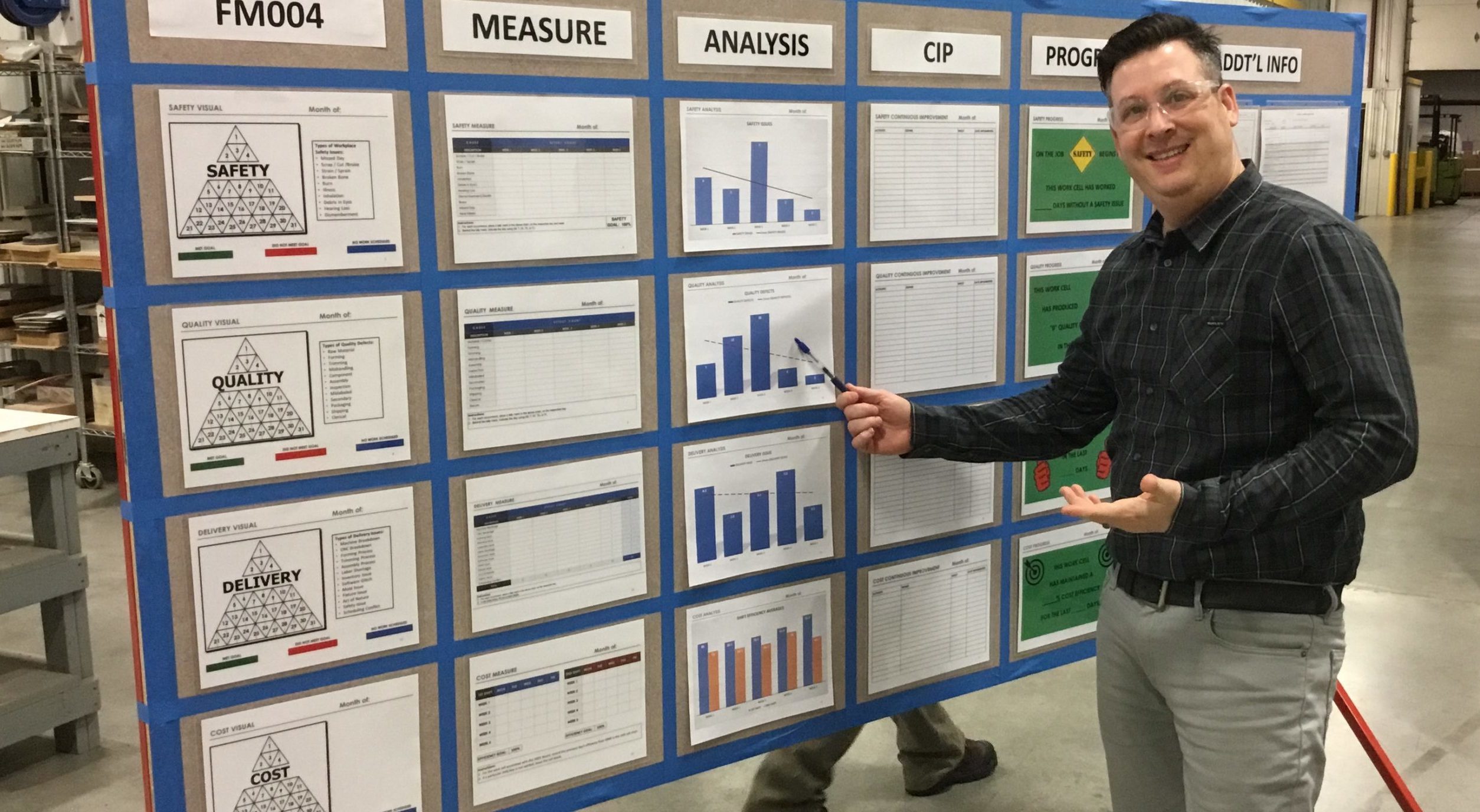

At SAY Plastics quality isn’t a department, it is an everyday standard that each and every team member strives to exceed everyday. Our customer’s expectations are high and we are glad to raise the bar to meet them. Each project is unique, each customer is special. We have a first rate facility to meet all our customer’s needs. We welcome you to visit us to see how we do what we do and what we can do for you.

Re-think, Re-engineer, RESULTS

Quality Tools

SAY Plastics understands the quality requirements of some industries can be more stringent than others. Whether automotive, rail, medical, or even material handling, SAY Plastics employs a variety of quality tools to meet every customer’s needs and expectations. Such tools include the following:

- PPAP (Production Part Approval Process)

- FMEA (Failure Mode & Effects Analysis)

- FAI (First Article Inspection)

- SPC (Statistical Process Controls)

- CAPA (Corrective and Preventative Action)

- SCAR (Supplier Corrective Action Reports)

- PDCA (Plan, Do, Check, Act)

- Root Cause Analysis – 8D Reports, Ishikawa Diagrams, 5Why’s

- Internal and Supply Chain Audits

ISO CERTIFICATION 9001:2015

Staying current with industry standards, SAY Plastics is ISO 9001:2015 certified for the Design, Thermoforming and Assembly of Plastic Products. Maintaining the most current certification meets two quality objectives. First, it assures that as a company we continue to manage our processes for accuracy and efficiency, helping us to maintain stability and competitive pricing during difficult economic times. Second, it provides our customers confidence that SAY Plastics conforms to the highest quality management principles.