With its global headquarters near Philadelphia, PA, CurveBeam products are made in the U.S.A. – with most major system components sourced locally.

For companies like CurveBeam that rely on U.S. suppliers to help build their products, finding a valued partner that can consistently meet production, quality and schedule requirements can be a challenge. So when you find a partner that checks off all the boxes, you keep them around. Which is why CurveBeam reached out to SAY Plastics when they began developing their latest CT imaging system.

SAY Plastics’ successful track record for new design ideation kept them at the forefront of the supplier list for the HiRise project, and CurveBeam’s final decision hinged on their proven expertise throughout the entire development process.

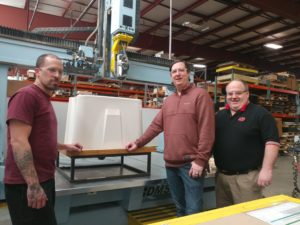

The HiRise system is an investigational product that takes CT imaging to another level – with multi-extremity capabilities for the lower body, knees, hips, and upper body. The unit measures approximately 58” high, 58” wide, and 73” deep.

The design complexity of HiRise required a comprehensive assessment of each system component. CurveBeam worked closely with SAY Plastics, leveraging their years of experience and ISO 9001:2015 certification in the Design,

“It’s great working with SAY Plastics – they have quick response and produced quality covers. We were able to harness their expertise to fit our applications beautifully.”

Through a collaborative approach, SAY Plastics was able to make several design recommendations to help with overall manufacturability – ensuring properly fitted covers and mitigating interference with other components to optimize system fit up.

To achieve HiRise’s sleek design, the unit required assembly of multiple mating parts of different draw ratios. When challenged to maintain the same gloss over parts with different geometry and height, tooling and process considerations are critical. SAY Plastics made design recommendations related to draw, draft, and radii and utilized closely managed time and temperature processing parameters to achieve a consistent, high-gloss cosmetic finish.

SAY Plastics also offered new design ideas to eliminate undercuts and lower mold costs. The post-machining of the unit’s molds held the tolerances needed for a multi-component fit up on a steel substructure – maintaining mating lines without gaps or the need for additional edge treatment.

Because of CurveBeam’s confidence in SAY Plastics’ design and engineering expertise, the project skipped the prototype phase and proceeded directly to production tooling. This resulted in significant cost savings by eliminating the need to prototype 8 different molds.

Several factors contributed to the successful development of the HiRise system:

✔ Collaborative approach between CurveBeam and SAY Plastics that utilized a complete design/engineering evaluation of the entire system. Early supplier involvement resulted in reduced time to market.

✔ Utilization of First Article Parts, made possible by SAY Plastics’ ISO-certified design program

✔ Team-centered approach using a dedicated Senior Applications Engineer, Project Manager, and Sales Specialist from SAY Plastics

✔ Comprehensive project management tools including Smartsheets and Microsoft Teams to ensure effective status monitoring, task changes, and schedule management

✔ Customer-focused approach with project transparency and ongoing communication to promptly address customer questions or concerns

SAY Plastics looks forward to supporting CurveBeam as they grow their product portfolio and extend their foray into innovative extremity imaging technologies.