Better Surface Protection Starts Here

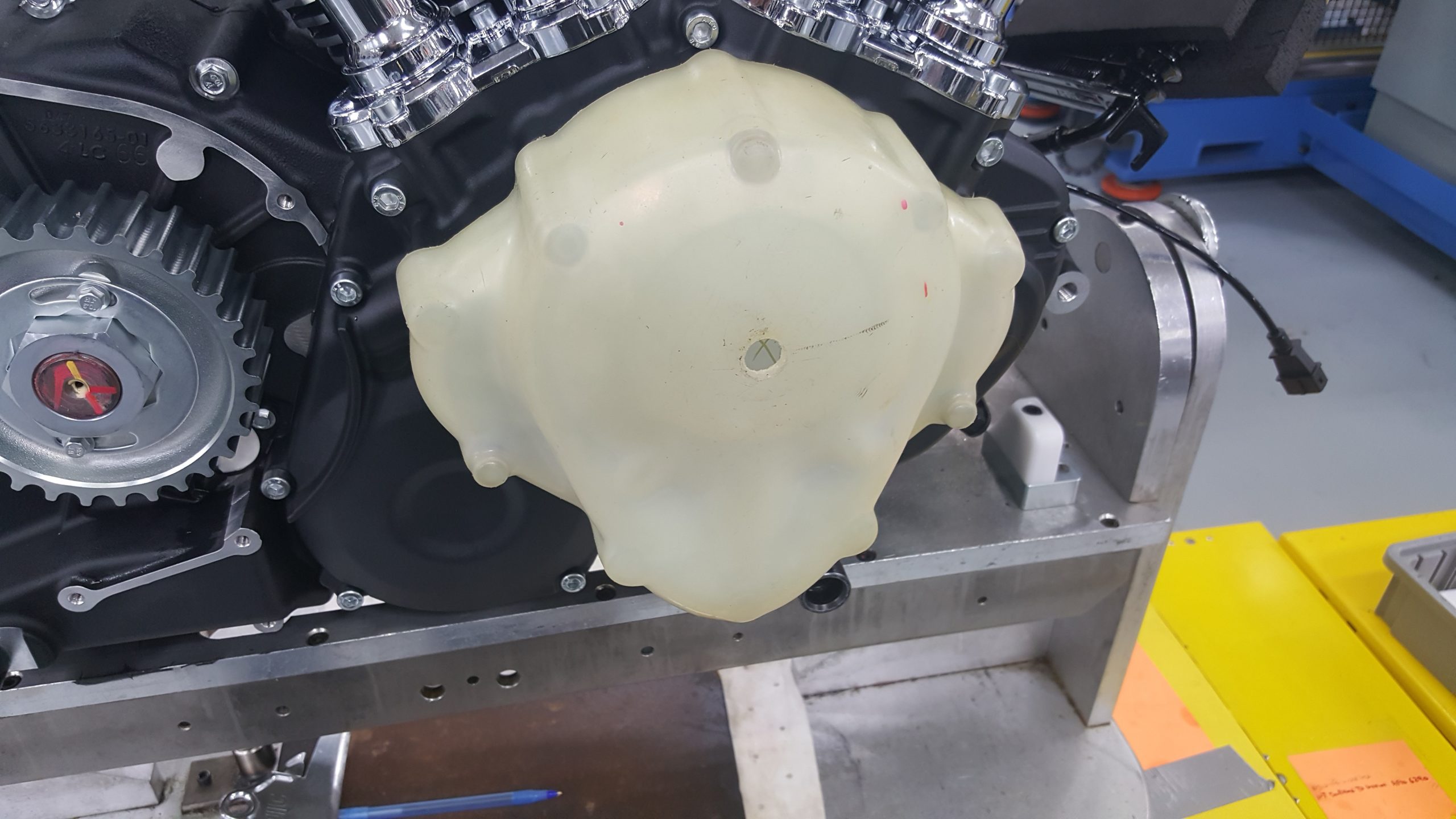

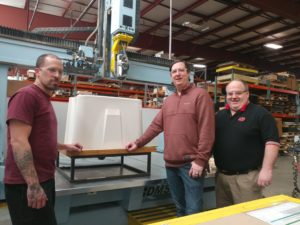

SAY Plastics is an ISO9001-2015 certified custom plastic solutions contract manufacturer. Certified in the design, manufacture and assembly of thermoformed plastic parts and components. SAY Plastics is your source for custom component and assembly protection solutions. Our innovative global surface protection solutions have a strong track record of reliable dunnage solutions for Class A Surfaces, as well as ISD Protection (In-Service Damage) and even material handling applications.

Surface Protection Solutions for Assembly, Storage, Shipping & Handling of Class A Surfaces

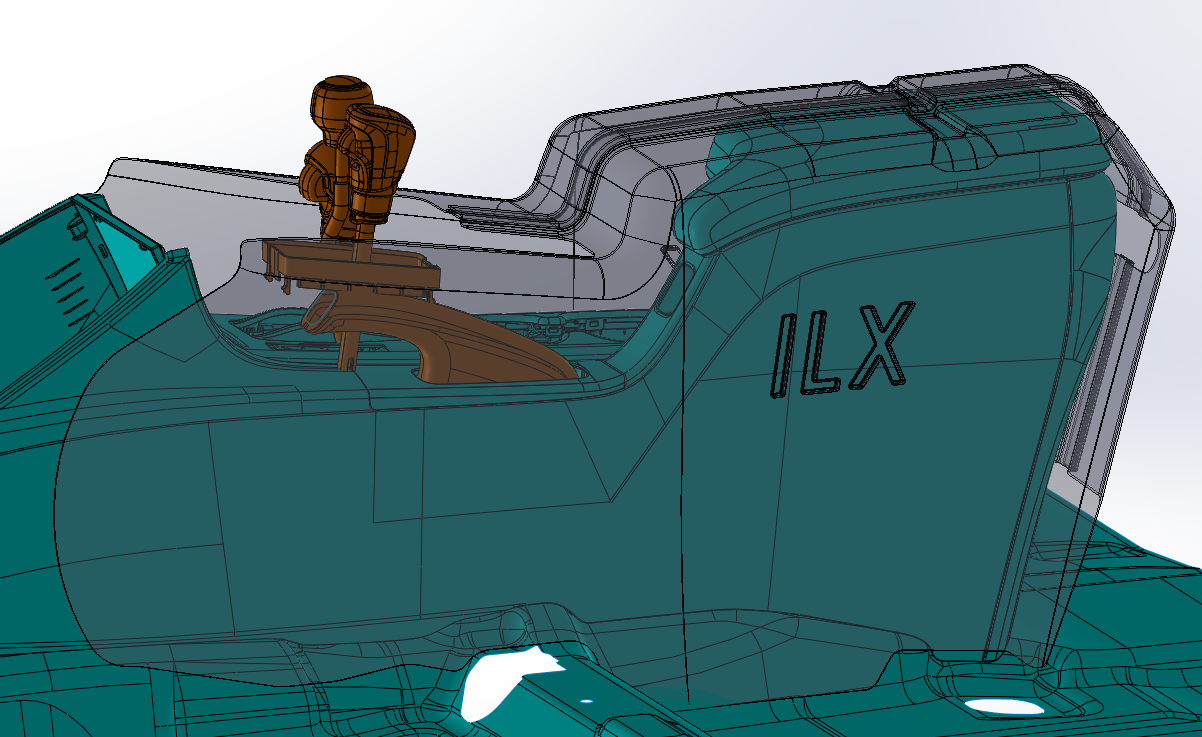

Customers from around the globe trust SAY Plastics Surface Protection Solutions to deliver reduced waste, cost savings and other efficiencies when it comes to their protection needs. Virtual 3D first articles have been the standard process for design reviews eliminating the need for a physical first article. Virtual First Articles (VFA) require no tooling or wait time for a production sample, saving customers substantial time and money among other advantages.

Virtual 3D First Article Process

- Virtual First Articles have been our standard process for design reviews saving customer’s time and money

- Requires no tooling or wait time for sample production

- Eliminates potential interferences during assembly process, addressing potential issues in the design phase prior to tooling being created

- Enhancing collaboration between us and the customer

- Each project has a dedicated design engineer, project manager and customer service specialist ensure timely communication

Benefits of Surface Protection

Cost Efficient

High Performance

Environmentally Friendly