Assemble, Store, and Ship

Assembly involves more than the ability to tighten a nut or stick on a label. Our ISO9001:2015 Certification for the Design, Thermoforming, and Assembly of Plastic Products ensures that SAY Plastics consistently manages our training and processes to deliver accuracy and efficiency.

OEMs save on labor, manufacturing space, and storage costs by having SAY Plastics provide assembly as part of our value-added service. We will source, procure and install all necessary components from hardware to decoration – relieving you of the need to work with additional vendors while leveling your workload.

- Component sourcing and procurement

- Adhesive Bonding

- Plastic Welding

- Mechanical Stress-free Attachment

- Hardware Preparation

- Silk Screen Printing

- Painting

- Work Cell Utilization

- Wire Harness

- Hot Stamp and Labeling

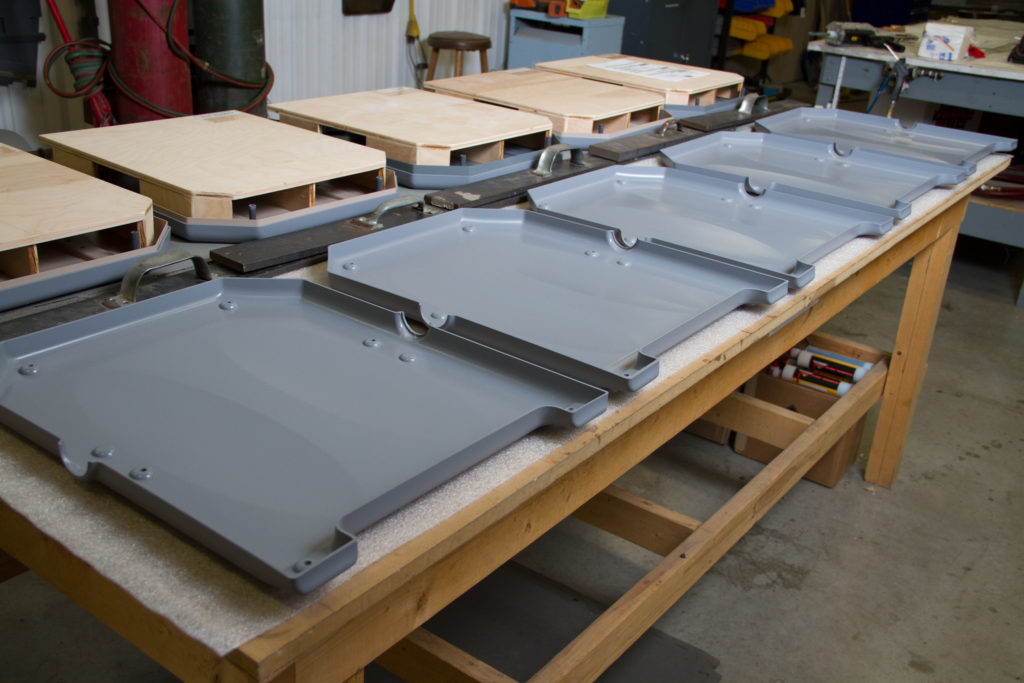

When you take advantage of SAY Plastics’ assembly expertise, your parts arrive ready to install. One of our experienced project managers will work closely with your logistics team to maintain inventory levels specific to your needs – and then ship your parts/assemblies as needed per your requirements.

In addition to our assembly and warehouse capabilities, SAY Plastics offers returnable packaging design and development solutions.

Benefits of Assembly & Logistics

Ready To Use

Labor Savings

Just In Time