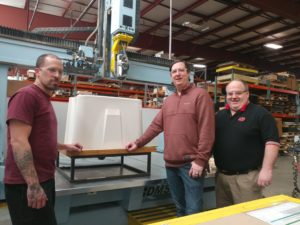

Welcome to SAY Plastics

ReThink. ReEngineer. RESULTS.

Since 1986, our company has leveraged our experience and the power of thermoforming to create world class thermoplastic solutions.

Learn MoreSAY Plastics is a custom plastic solutions contract manufacturer. We are ISO9001-2015 certified in the design, manufacture and assembly of thermoformed plastic parts and components.

We work with companies who are uncertain what process is right for their new project. Our customers tell us that other supplier’s lack of design expertise coupled with a general approach that all projects are the same causes upfront concerns that their project is not getting the attention it deserves. SAY Plastics works closely with our customers to ensure no detail is left out. This ability to work closely with our customers is only possible with complete and open communication between us and our customer. We strive for all projects to be successful projects and this starts with communicating with each other.

When you work with SAY Plastics, you’ll quickly see that thermoforming offers a number of advantages over other materials and manufacturing processes.

- A proven, engineering-tested manufacturing method

- Delivers big savings in terms of tooling development time and cost

- Low cost quick to market solution for new projects

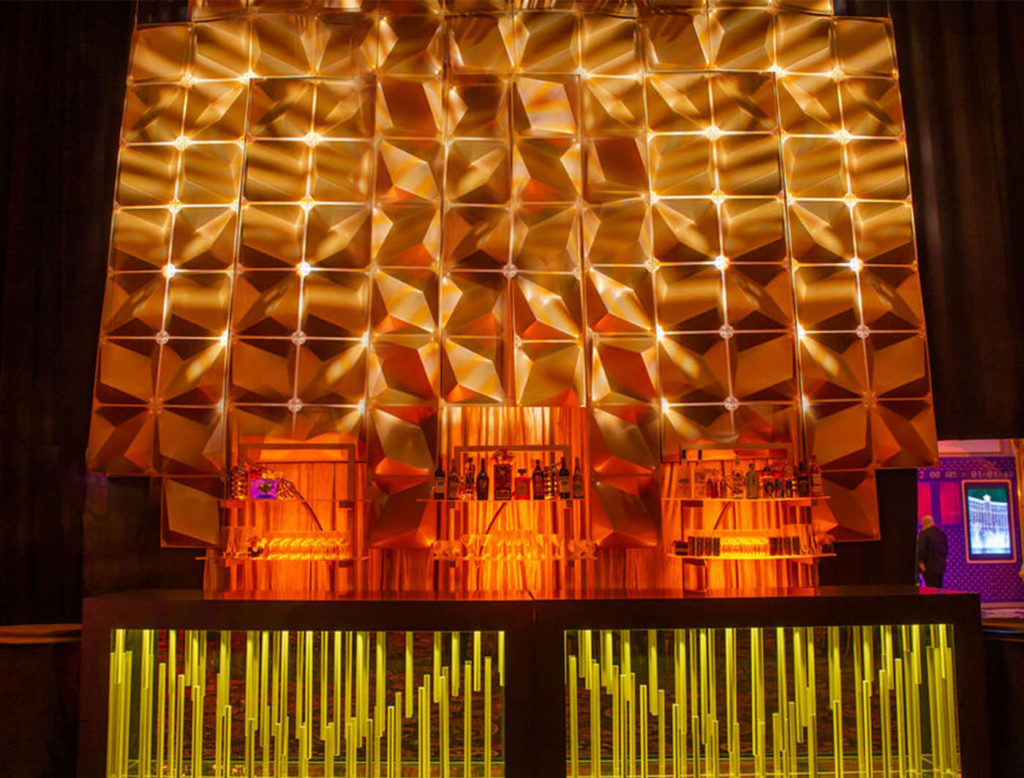

- Provides flexible design solutions not possible with other processes or materials

- Materials are recyclable, non-corrosive and available color matched with UV protection

- Customizable – can be extruded or laminated with multiple layers

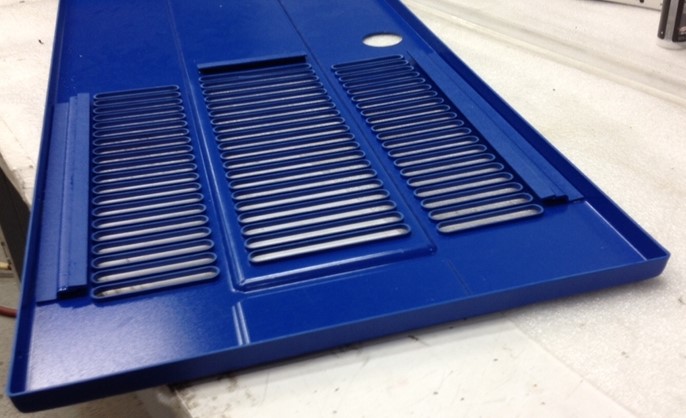

- Cost-saving conversion solution for all types of FRP and metal parts and applications

- Thermoplastic is lightweight, impact resistant, and durable with great part-to-part consistency

- Very economical option for all volume levels

SAY Plastics, Inc. is an industry leader in the development and manufacturing of thermoplastic components and assemblies.

We provide solutions for OEMs/Industrial Manufacturers and Material Handling applications in a variety of industries.

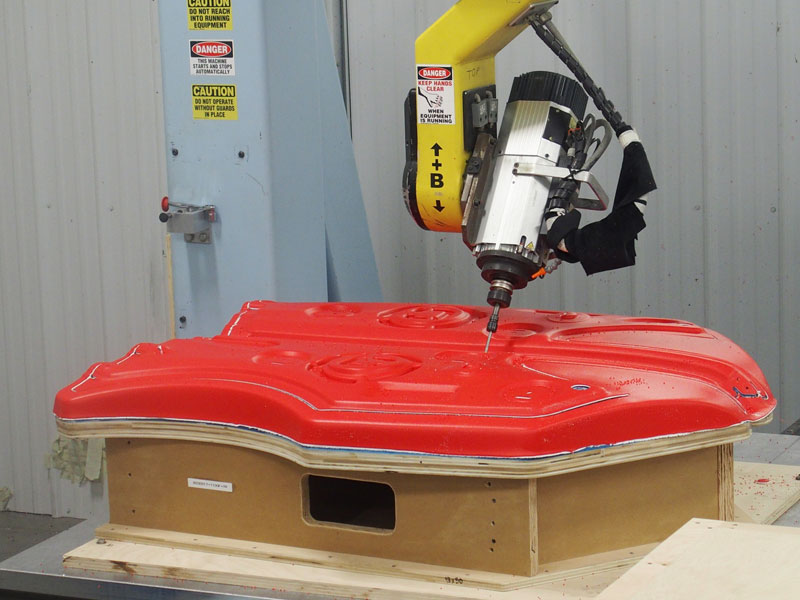

- Thermoforming/Vacuum Forming

- Pressure Forming

- 5 Axis CNC Trimming

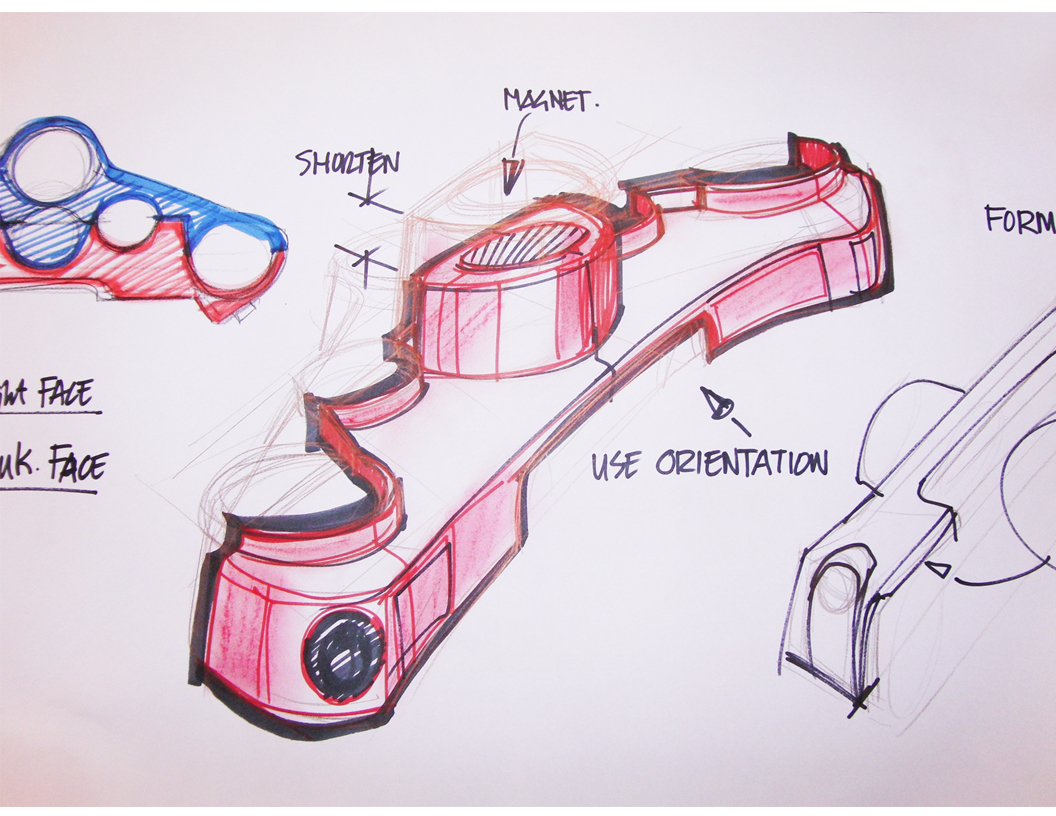

- Design and Development

- Assembly

- Additive Manufacturing (3D Printing)

- Fabrication

- Tooling

- Silk Screen Printing