Unique Projects Require Unique Tooling

We offer a very industry unique approach through our tooling development system which provides a cost-effective entry for new product development and start-up projects, as well as high-volume programs.

Our SAYtooling System begins with a comprehensive evaluation to determine the best approach for the project and ends with a highly innovative tooling development execution. We carefully assess the material to be formed, its processing characteristics, project type (start up, low-production, high-production), cosmetic requirements, tooling budget, timeline and other program parameters.

The right tool for the job!

SAYtooling System Benefits

- Unique cost-saving tooling for your application

- 50% faster lead time

- 30% cost savings

- Facilitates Process Conversions (FRP and Metal to Thermoforming)

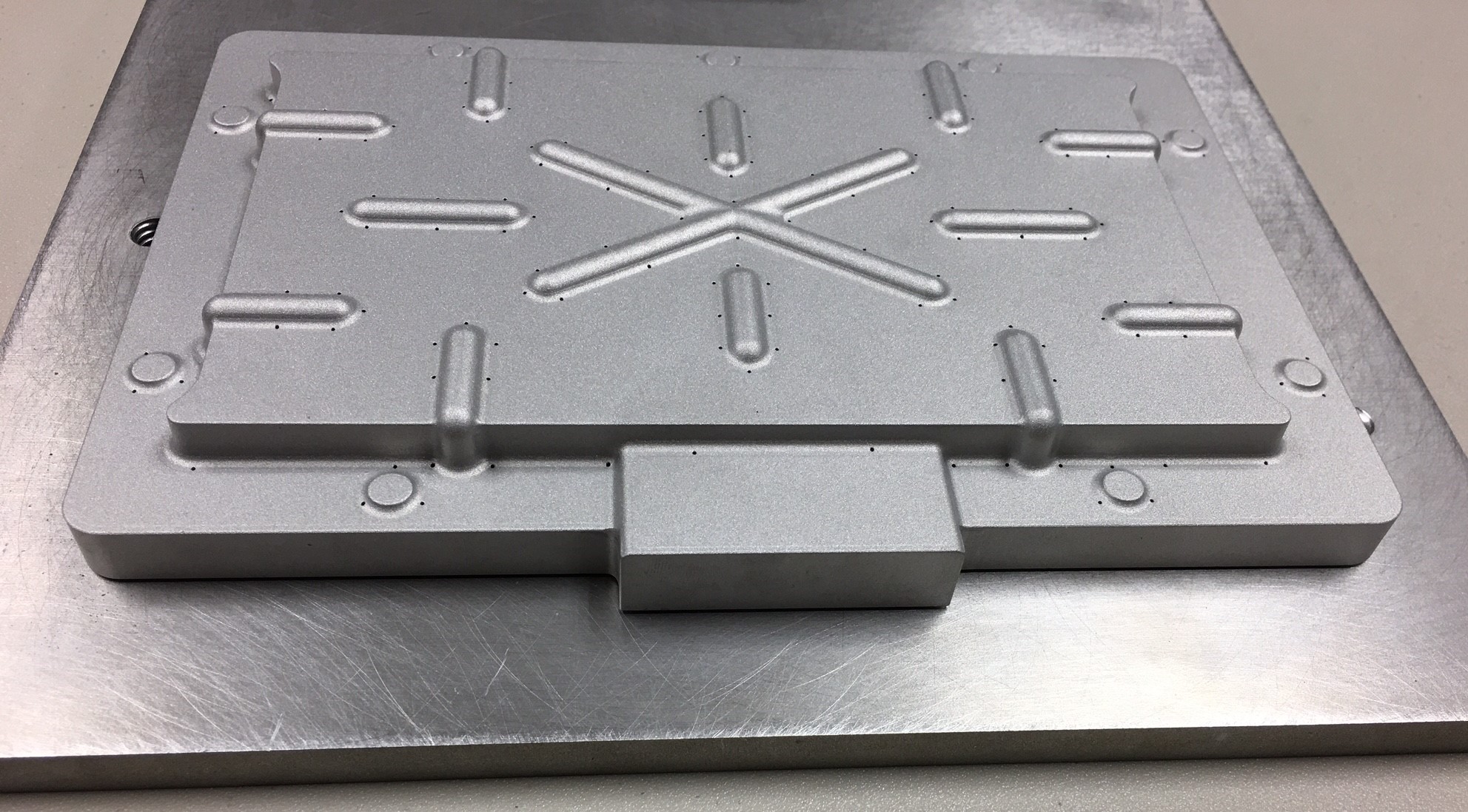

Tooling Material Options…

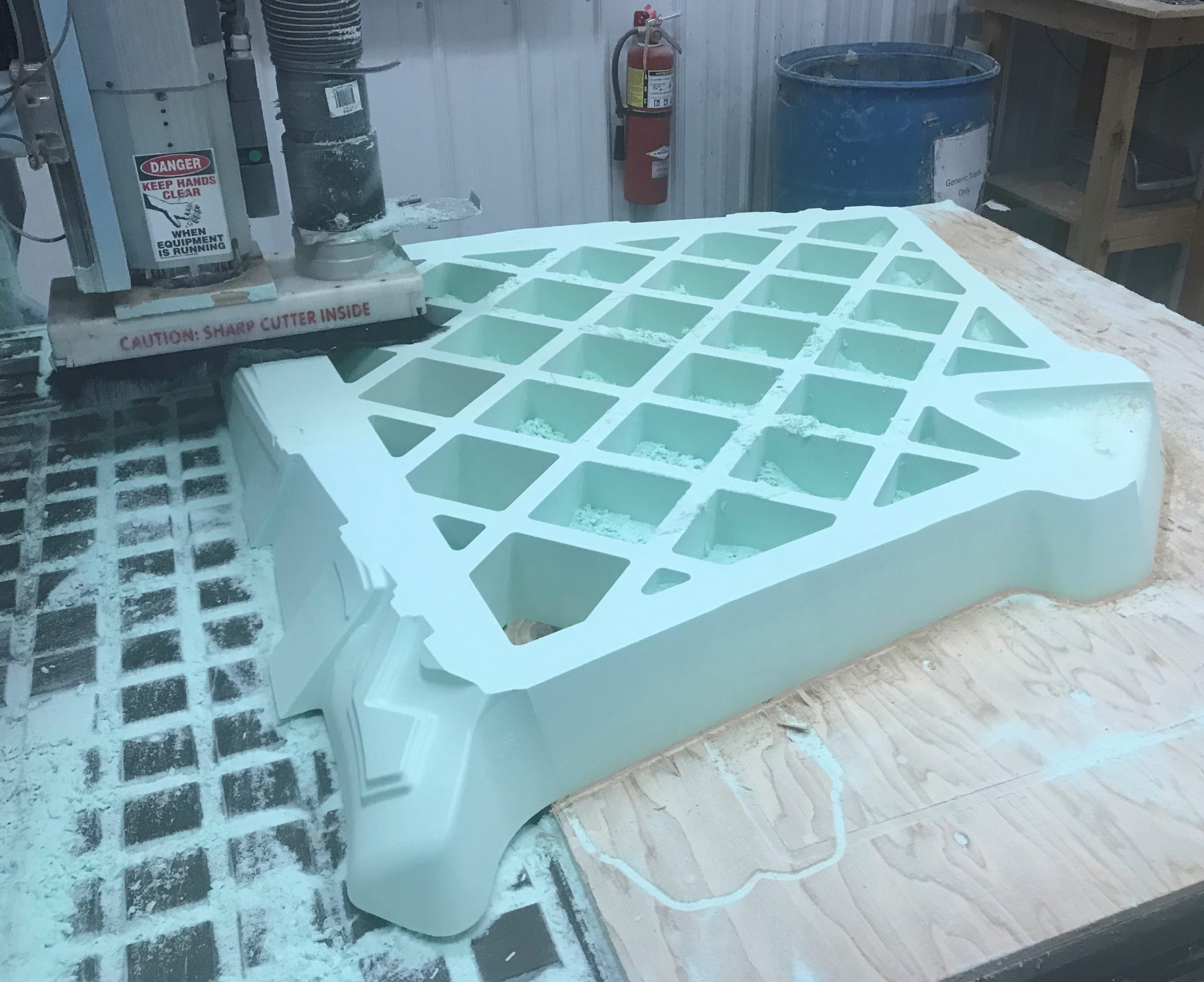

- High Density Foam

- Urethane Tooling Board

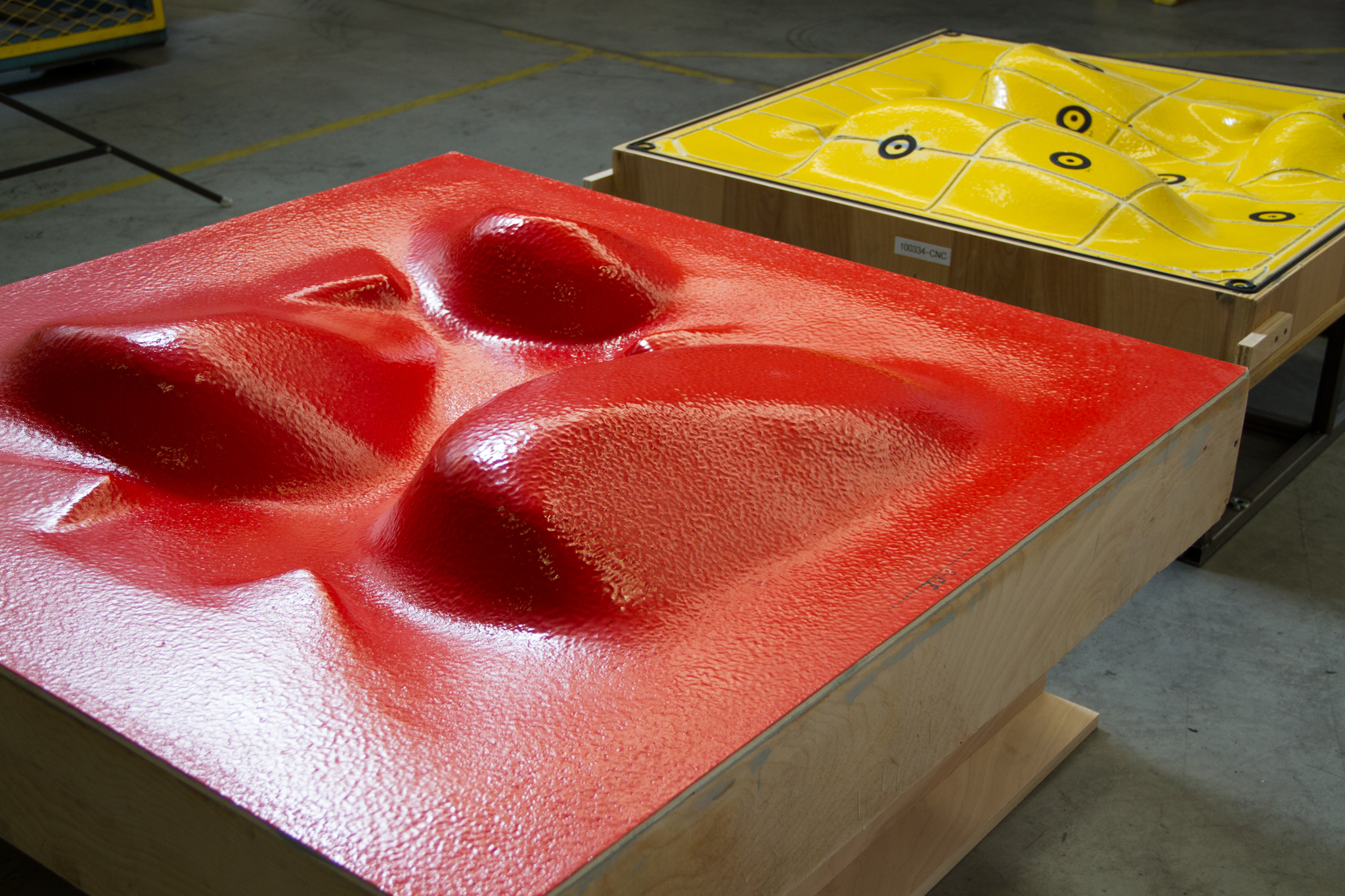

- Cast Urethane

- Syntactic

- Fiberglass Reinforced Plastic

- Ceramic

- Cast Aluminum

- Machined Aluminum

Our Process includes key elements for superior results…

- Expert Project Engineers to define process parameters

- Trained Plastic Process Technicians

- Meticulous Quality Standards

- Project Specific Deliverables

Benefits of Our SAYTooling System

Project Specific

Fast Turnaround

High Quality