Next Generation Production Monitoring:

RealTime™ System Helps Take SAY Plastics to the Next Level

SAY Plastics has been a long-time user of DELMIAWorks’ (formerly IQMS) ERP software system. It’s a leading industry solution used by manufacturers of all scale to bring more efficiency to critical processes, from sales and order management to production and inventory.

Like any good technology platform, new upgrades and system modules are regularly introduced – with the goal of enhancing a facet of the ERP system and giving manufacturers new advancements to invest in, so they can further optimize operations for the benefit of their customers.

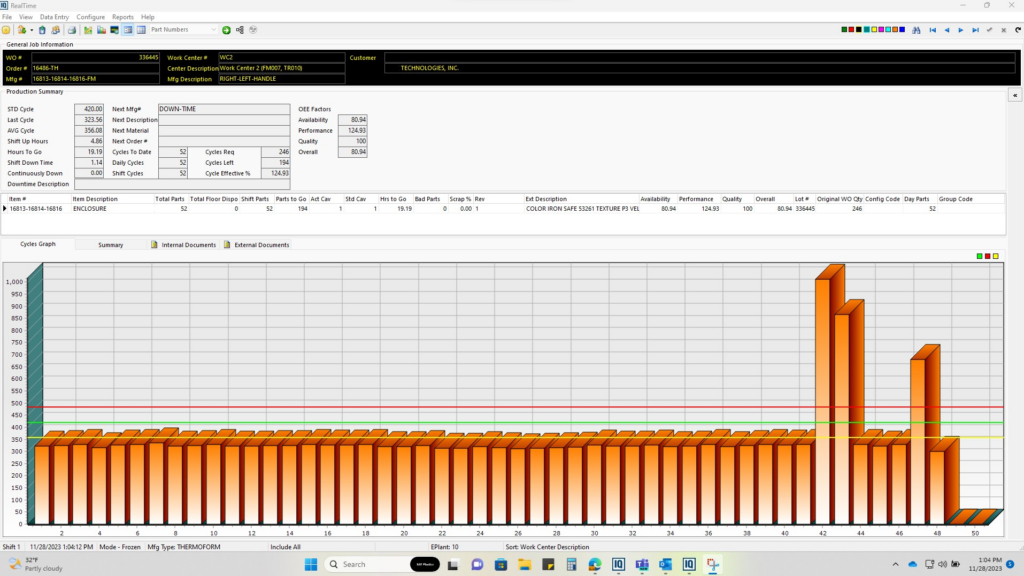

One such investment this year for SAY Plastics was the addition of DELMIAWorks’ RealTime™ Production module, which, in just a few short months, has taken our real-time production monitoring to the next level.

More About the Realtime™ Solution

The RealTime™ system is fully embedded within the ERP and features a wide ranging suite of manufacture monitoring and data collection tools. These tools can track all aspects of job production in real-time such as scheduling details, machine setup time, hourly production output, downtime stats, scrap details, and quality performance data.

SAY Plastics completed our RealTime™ integration earlier this year and the system is used on all work cells throughout our production facility.

Some added bonuses of the module were the seamless installation of the RealTime™ sensors into our machines, easy in-house staff training, and low maintenance needs. RealTime™ also eliminates the need for a third-party interface, which reduces monitoring expenses.

Web-based data gives our teams both on and off the production floor easy and immediate visibility into all the critical job parameters mentioned above. For non-operator team members, a big advantage is the ability to access important data from anywhere at any time – without being on the production floor.

The Big Benefits

So what are some of the other benefits that RealTime™ provides to us, and ultimately to the clients who partner with us?

Less Downtime, More Productivity. Thanks to real-time data and actionable insights, we’re able to take better control of our work cells – flagging inefficient machine performance before it becomes an issue. This eliminates problematic downtime and keeps productivity high – so schedules are maintained and orders are delivered on time.

Better Customer Data. The real-time, “hands-off” data capture capabilities of RealTime™ also eliminate redundant data entry across the organization. This improves the accuracy of our customers’ critical data, so we can communicate precisely when a job will be completed, and when it will ship.

Customization. The performance and measurement criteria for each job that we have in production is completely customizable in RealTime™. The data collected is based on each customer’s specifications; we have the flexibility to deliver whatever job-specific statistics may be required.

Results To-Date

By addressing downtime and underperforming run efficiencies as identified by RealTime™, SAY Plastics was able to increase our production capacity by 8% in just the first several months of our RealTime™ integration. Continued use of this valuable system will only deliver more improvements as we move into the new year and beyond.

Learn More

Schedule a consultation with SAY Plastics today to learn more about our latest technology innovations and how they can be leveraged for your next thermoforming project.