Thermoforming Benefits

Our customers use thermoformed plastics to reduce costs, decrease weight, enhance appearance, increase durability, and provide long-lasting products.

Just a few advantages of thermoforming…

- Cost Efficient

- Quick Turnaround

- Design Flexibility

- Reduced Weight

- Corrosion Resistance

- High Impact Strength

- Eliminate Paint

- Unlimited Appearance Choices

What is Thermoforming?

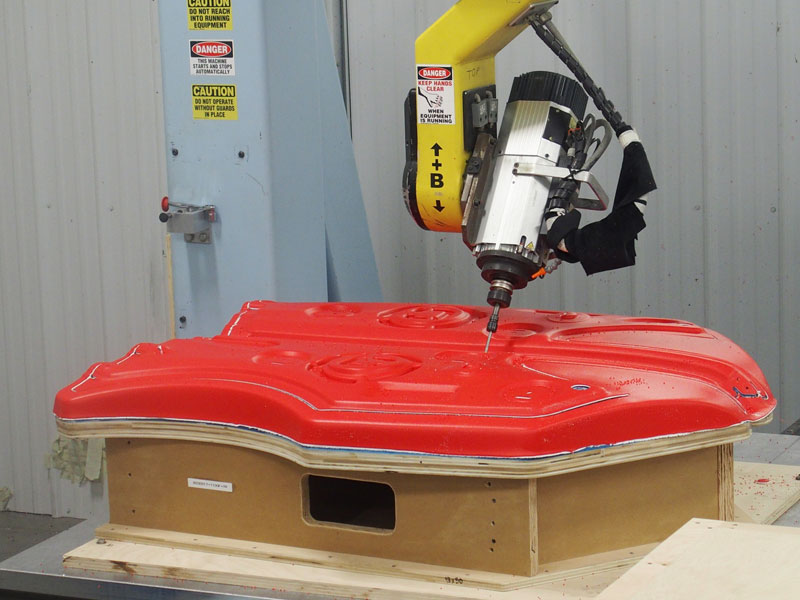

Thermoforming is where an extruded plastic sheet is heated to a pliable temperature, formed to a defined shape by use of mold and vacuum, and CNC trimmed to create a finished product.

Thermoforming Capabilities at SAY Plastics include…

- Single-sheet vacuum forming from smaller than 6″ square to as large as 5′ x 7′ with 3′ deep draw

- Pressure forming

- Assembly, bonding, inserting, and decoration

- CNC robotic trimming (3 axis and 5 axis)

- Material and product trace-ability

Benefits of Thermoforming

Metal and Fiberglass Alternatives

Quick to Market

Design Flexibility