Featured Article

SAY Plastics Launches New Robotic Trim Center

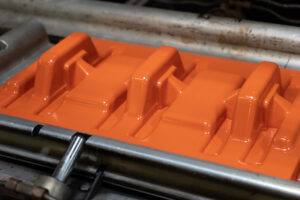

We’re excited to announce that SAY Plastics has added another innovative technology to our thermoforming toolbox – a new, state-of-the-art robotic trim center that allows us to further enhance our manufacturing processes and produce quality thermoformed solutions with greater precision and speed for customers. In the short time since we integrated this new equipment into our workflow, we’ve already experienced significant payoffs including a nearly 80% reduction in trim cycle time on our first project. Rise of Robotics The use of robotics … Continue Reading