We’re excited to announce that SAY Plastics has added another innovative technology to our thermoforming toolbox – a new, state-of-the-art robotic trim center that allows us to further enhance our manufacturing processes and produce quality thermoformed solutions with greater precision and speed for customers.

We’re excited to announce that SAY Plastics has added another innovative technology to our thermoforming toolbox – a new, state-of-the-art robotic trim center that allows us to further enhance our manufacturing processes and produce quality thermoformed solutions with greater precision and speed for customers.

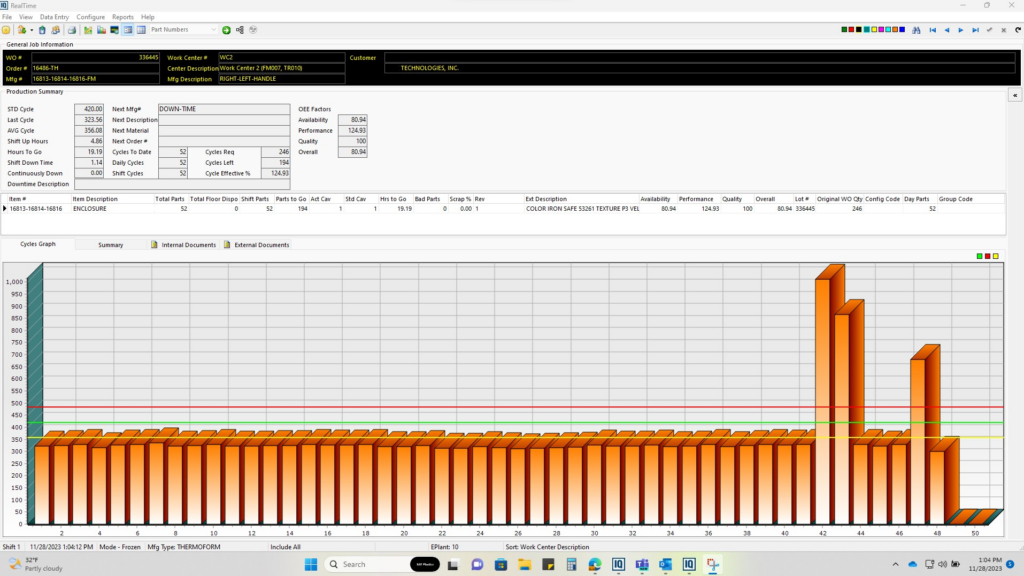

In the short time since we integrated this new equipment into our workflow, we’ve already experienced significant payoffs including a nearly 80% reduction in trim cycle time on our first project.

Rise of Robotics

The use of robotics in manufacturing has progressed greatly in recent years. What started as simple, fixed automation solutions for primarily material handling and auto manufacturing has evolved into flexible, highly sophisticated systems that take modern-day manufacturing precision and productivity to a whole new level.

The cost of investing in robotics for manufacturing has decreased over the decades thanks to economies of scale, increased competition, and new tech advancements that make robotic solutions more affordable. What was once considered an exclusive offering for large-scale manufacturers is now much more accessible for producers of all sizes. This of course has contributed to greater adoption across a wide range of applications in just about any industry you can think of.

SAY’s 7-Axis Robotic Trim Router

SAY Plastics’ new work cell features a 7-axis Robotic Trim Router that uses an articulated robot from ABB Robotics, one of the world’s leading robotics and machine automation suppliers, with a 150” by 60” rotating double sided table.

Before our new robotic trim center, we utilized a 5-axis CNC Router to manufacture a variety of thermoforming projects with varying complexity and tolerances. While this CNC technology was highly reliable for us in part quality and machine performance, the significantly higher throughput that robotic automation is capable of was of particular interest to us for high-volume production jobs.

The speed, accuracy, and repeatability of a robotic trim center is unmatched. On our first project, we reduced a 24-minute trim cycle time down to a 5-minute trim cycle time by moving from the 5-axis CNC Router to the 7-axis Robotic Trim Router.

While the performance of our new work cell has clearly paid off with our very first project, we continue to bring in more projects and leverage our new technology to shorten cycle times even more.

Additional Benefits

Although the biggest benefits of a robotic trim center are by far speed, high accuracy, and consistency, the technology does provide additional benefits:

Enhanced Safety. Robotic work cells are equipped with state-of-the-art safety features that minimize risks and create a safe working environment for operators. SAY currently has three programmers and operators expertly trained in managing our work cell.

Energy Efficiency. RobotStudio® Suite allows for streamlined setup and programming measures to its highly efficient production capabilities, robotic work cells are designed to optimize energy consumption. And its speed and accuracy significantly reduce scrap, as well as wasteful downtime.

Increased Capacity. Robotic integration allows manufacturers to boost production capacity and handle larger volumes of work without comprising part quality.

Customization. Robotic work cells are adaptable to a wide variety of product specifications, which allows manufacturers to more easily accommodate customer requirements. As project scopes evolve and become more complex, robotic automation can evolve and adapt with it.

Learn More About Robotic Trimming for High-Volume Projects

Explore the benefits of robotic trimming for your next high-volume thermoforming job. Connect with the experts at SAY Plastics to schedule a tour of our facility and see our technology in action.